Invented by the Chinese in the 900s AD, screen printing has survived until this day because of its versatility, durability and efficiency. And thanks to innovative minds, you can now mass produce quality garments in record speeds.

And with personalization and commercialization on the rise, the demand for custom made apparels are bigger than ever. Grand View Research recently valued the global custom printing market at $3.4 billion in 2019 and is expected to grow to $6.9 billion by 2027!

While all this sounds great, you are still confronted with a more technical question – screen printing vs heat press vs Direct To Garment (DTG) – which method is the best for you?

Today we’ll explore the most popular methods of garment decoration, their respective pros and cons and what’s available in the market.

We’ll compare the good, bad and ugly to determine what sets traditional screen printing apart from the rest and how this ultimately affects you.

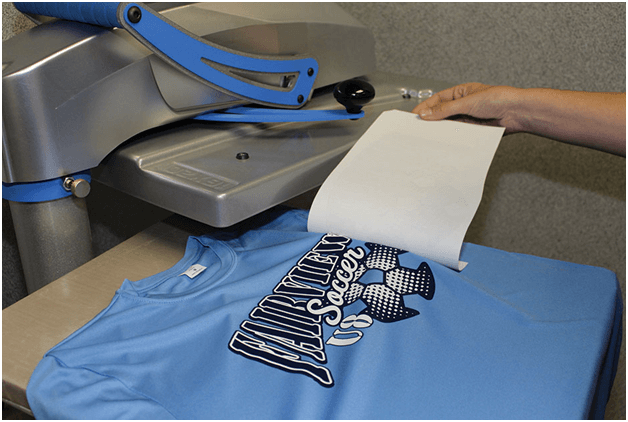

The low down on heat pressing

So you probably heard of heat press transfers. You also probably own a few heat pressed t-shirts yourself.

But what is it and why has it become so popular?

In its simplest definition, heat pressing is a method of pressing a papered design onto a garment using a heat press machine.

To successfully embed a design onto fabric, a specific temperature (typically 300-400 degrees Fahrenheit) and pressure (40-80 PSI) is required.

Heat pressing can be divided into different categories depending on the materials used, these include:

Regular Heat Transfers (Inkjet and Laser)

The easiest way to get started with heat pressing as you only need a few materials

- a laser or inkjet printer

- heat transfer paper

- heat press machine

In this method, use an inkjet or laser printer to print your image on the special “transfer papers” – a thin piece of paper coated with wax and pigment. Then use a heat press machine to transfer the image onto clothing, canvas, or any other surface.

Less durable transfer papers can also be used to create iron-ons which can be found at your local flea markets or malls. These are perfect for one-off projects as the quality of these transfers are limited.

However, recent advancements have produced commercial grade transfer papers that are impressively vibrant and longer lasting.

Plastisol Transfers

Similar to regular transfer papers, an image is applied to a special plastisol transfer paper first and is subsequently transferred to the fabric using a heat press machine.

The only difference is how the image is applied onto the special paper.

For regular heat transfers, you use an inkjet or laser printer. For plastisol transfers, traditional screen printing using plastisol ink is used.

That’s right – the same process of screen printing is used but instead of printing on garment, we’re printing on a piece of plastisol transfer paper.

And since typical screen printing method is used, garments with plastisol transfers last as long as regular screen printed ones.

Plastisol transfers work best on cotton, nylon and polyester fabric.

Plastisol transfers make it easy to print apparel on-demand without the need to havea huge screen printing press. You can press on a shirt for 10 seconds and you get the same quality as screen printing without cleaning up a mess. Plastisol transfers work best on cotton, nylon, and polyester fabric.

Vinyl Transfers or Die-cut vinyl

These thin layers of colored vinyl usually come in two types – adhesives ones and non-adhesive ones that require a heat press. I’m going to talk about the non-adhesive type.

The process of of getting the image is the same for both types – using a plotter machine or die-cutter, the design is cut and “weeded” – the process of pulling away extra vinyl around the design – before being fused to the fabric using a heat press.

Heat press vinyl transfers are commonly seen on sportswear like jerseys and track suits but can also be found on tote bags, coats, scarves, blankets, stuffed animals, etc.

Aside from regular colors, you can find metallic or glitter like vinyl to add some effects on the garment.

Unlike ink, vinyl transfers are durable as they last a long time with zero fading and peeling.

Sublimation transfers

Sublimation printing or dye-sub, uses paper with a special coating added to it to hold dye sublimation inks. When heat is applied, it turns the ink into gas which is then cured directly into the fabric.

This results in a soft-hand, vibrant and permanent print that is durable and less prone to fading and peeling.

Suitable for smaller batch orders and ‘all over’ printing – prints that are go from seam to seam such as on socks and shorts – this print method however, does have its limitations.

Due to the process itself, sublimation isn’t as versatile as screen printing and works best with specific materials – polyester (100% polyester or polyester blend) – and select designs – designs that do not require exact placements.

Rhinestone transfers

These type of transfer paper contain tiny crystal and diamond like pieces of acrylic or plastic are called rhinestones.

Hot-fix rhinestones typically make up the majority of rhinestones in the garment decoration market today. On the back of these these glittery gems contain heat-activated adhesive that fuses to the garment when heat pressed onto fabric.

With hundreds of various shapes, sizes and colors, rhinestones can be applied onto most fabric including t-shirts, leggings, dresses and bags. And because it’s a straightforward and economical process that enhances a garment’s perceived value, it’s become one of the leading methods of decoration.

But with all its trendiness, rhinestones can be a time-consuming process, particularly in dealing with multi-colored designs. It shines in small batches, but scaling this method is not ideal.

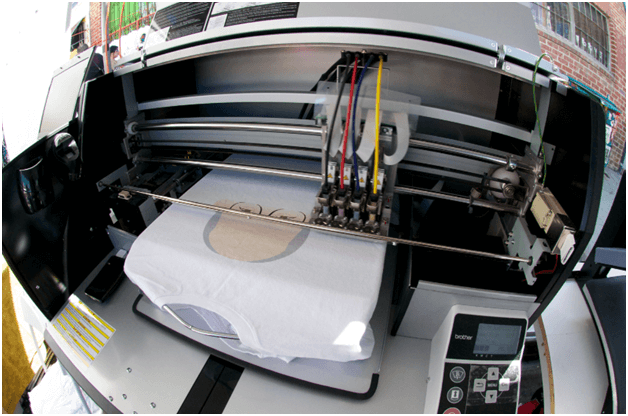

Direct-to-Garment printing and why it matters to you?

DTG printing, short for Direct To Garment, has been around since the early 2000s.

It wasn’t popular in its early years, but the rapid advancement of technology made this printing method more affordable and faster as well for producing high-quality prints.

In short, the DTG method works by spraying ink onto the garment and soaking it into the fibers. Think of it like paper printing, but on clothing.

Since it works exactly like a printer, DTG can support the most delicate and detailed designs, with as many colors as needed.

As a matter of fact, the majority of online printing companies such as Redbubble, Society6 and Threadless are also now using DTG machines in their production line.

However, the one barrier that’s keeping most individual hobbyist from getting in on the action is the relatively high price of these machines.

Basic ones cost between $10,000 and upwards for reputable brands like Epson F2100, Brother GTX and Col-Desi DTG M2.

But as DTG gains popularity and momentum, cheaper ones from HRM and Automatic are starting to flood the market. Some innovative minds have also started to build their own homemade machines.

But the question remains – what’s it like when you pit traditional screen printing vs DTG?

I’ve picked out several important bits and compared them.

If you’re serious about either method, check out the sections below to get a better idea of the pros and cons.

Vibrancy: Which method catches the eye more?

If you want the vibrancy of the design to stand out and impress, then go with screen printing. Although DTG has come a long way and the tech is continuously being improved over the years, it is still slightly duller compared to screen printed apparel.

But why?

Typical screen printing uses opaque inks that are available in a broad range of exact vibrant colors.

DTG however, uses water-based inks that are semi transparent due to its CMYK system of printing. And while it’s possible to improve vibrancy by tweaking specifics e.g. adding a white under-base on dark garments, it generally still lacks the “pop”.

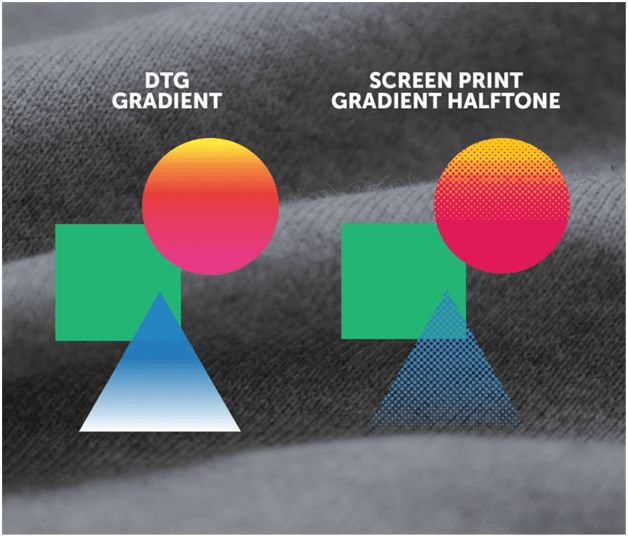

Blending Colors: Both can handle process printing, but which one reigns supreme?

The ability to blend and create smooth gradients and an array of colors is where DTG printers excel.

By default, the DTG system uses CMYK (Cyan, Magenta, Yellow and Black) colors in its print setup. In screen printing, this is commonly known as 4 color process printing with the use of halftones.

DTG printing is able to produce true-to-life photographic gradients with smooth transitions, precise blending on skin tones and subtle elements like smoke. And it does so with minimal setup since it works much like your home inkjet printer.

Screen printing is also able to achieve the same complexities with halftones. However, the required setup is quite specialized to say the least.

Acquiring the skill has quite a steep learning curve not just in practice and experience, but also when it comes to the technicalities of color separations.

With the less-than-easy setup involved, screen printing loses out to DTG when it comes to creating a spectrum of colors with the simulated process.

Exact Match Colors: I need the colors to match on-screen and in real life

Accurately matching colors is important, especially in terms of corporate branding. Most companies will provide strict brand guidelines that specify Pantone colors.

And if you use DTG to match those colors, it will almost always go off – especially when printing on dark colored garments.

Because of the problematic under-base layer, which is not opaque enough, the color of the garment bleeds and thus begins the headache of color matching.

In screen printing however, you can duplicate any color you want using the Pantone Matching System. That includes the colors that are outside the CMYK range as well as specialty inks and super-saturated colors.

So, if matching the exact colors is a strict requirement from you, then take a ride with screen printing.

Fine Lines: The devil truly is in the details

When it comes to printing, details are the fine lines, tiny fonts, subtle highlights, tiny elements and textures of a design.

In screen printing, it’s all about “holding” these minute details. So, if you are not holding it, then you are losing it. Several factors affect details in screen printing. These include:

- Ink viscosity

- Screen tension

- Surface properties of the fabric or material being printed on

- Speed and pressure of ink application

- Squeegee angle and sharpness

- Ink spread

If your design has a gradient or is photographic, then halftones are required.

However, most halftones for screen printing are produced by RIP programs at anywhere from 30 to 65 LPI – the lower LPI, the dot gets bigger.

But even at a high LPI, these dots will be visible if you look closely. Also, if the ink gain becomes a problem, then each dot will spread out, making it more visible and bigger.

DTG printing on the other hand, uses halftones as well.

But these printers can print up to 1,200 DPI! This results in a grainy look, but with better reproduction of finer details.

Hands down, DTG produces better details.

Durability: Which print stays on longer?

When talking about print durability, we’re talking about how long the quality of the print lasts. DTG struggles most in this area.

In its early days, DTG prints can last up 10 washes before it starts fading.

Today, that number has increased into the dozens, but not without compromises.

Manufacturers are constantly experimenting – from the inks used to the under-base, pre-treatment to curing time, the DTG way is ever evolving.

But even with the right tweaks, a well-done DTG print will fade faster than traditional screen prints, which are known to last decades.

Touch and Feel: Which is the softest of all?

You’re wearing a killer design, but damn, that t-shirt is not comfy!

When talking about comfort and feel, it means:

- Does the print feel heavy on the t-shirt?

- Does the ink clog up the fibers of the fabric? Thus reducing its breathability.

- Does the texture feel uncomfortable or rough on the skin?

In screen printing slang, the touch or feel is also called the “hand”.

So, if a customer request for “soft-hand” then they want a smooth print that is usually produced by using water-based or discharge ink.

If you’re using plastisol inks, you need to thin the ink down with an additive in order to make it more lightweight and smoother on the shirt.

Some screen printing techniques like the “distress effect” can also create a soft hand. It reduces the amount of surface area that the ink occupies and breaks it up so that it is more flexible.

In the area of “hand”, both DTG and screen printing are able to produce comfortable and smooth prints, giving this a tie.

Versatility: If you want to print more than just flat surfaces.

Versatility refers to the ability to print on various textiles as well as various garment styles, placements, and print locations.

When it comes to DTG, its versatility is somewhat limited.

Although DTG can now print on a broader variety of textiles and fabrics, many still recommend 100% cotton. And while there are newer systems that claim to work with different types of fabric, they are not widely used in this industry.

Meanwhile, screen printing works on polyester, cotton, canvas, blends, denim and even moisture-wicking and performance fabrics like rayon. And you can print on any color garment you want.

In terms of garment style, if you are printing on basic hoodies or t-shirts, DTG is favorable. However, if you need to print on something like hats, go with heat pressing or embroidery.

The bottom line is, if you want versatility and fewer restrictions on printing location, screen printing is the best.

Consistency: Which method is best used to scale?

In terms of producing consistent prints, I feel screen printing has a small advantage over DTG. For the most part, it all boils down to the nature of each processes.

While DTG is convenient, automated and pretty much a passive activity once you hit ‘print’. There are variables that are harder to control, not to mention more expensive to fix e.g. clogged print head comes to mind.

Having said that, screen printing isn’t void of headaches when it comes to printing large orders.

Clogged mesh, bad screen tension, expired ink, dull squeegee, wrong placement, etc are all factors that will cause you to flip the table. However, the maintenance of screen printing equipment and materials are far easier to deal with when things go south.

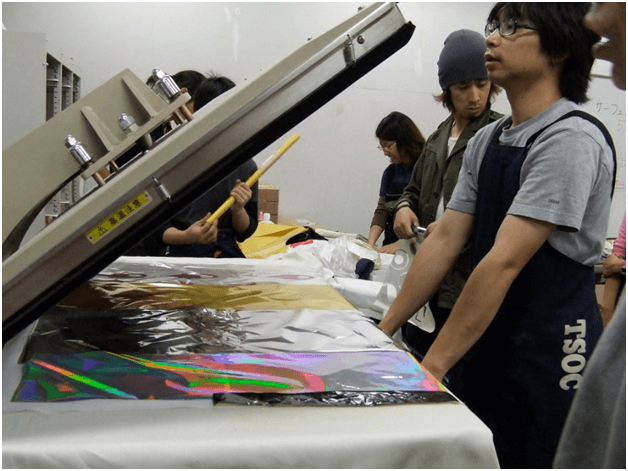

Screen printing specialty inks and other options to make your t-shirt pop!

In terms of adding special effects, DTG doesn’t stand a chance.

Special effects printing is all about adding that extra pop and dimensions to a print.

From the shines, glows and sparkles to raised prints and texture, there is a specialty ink screen printing can do.

And the best part of it, you can combine as many of these unique inks and additives for creations that are limited only by your imagination.

Here are some of the most common specialty inks available in the market today:

Glow in the Dark

These inks are almost clear and are effective in complete darkness, radiating bright green color.

Metallic Gold and Silver

Metallic screen printing produces a luxurious matte finish to prints on fabrics. One of the most popular specialty screen printing methods today, metallic ink printing combines small particles of copper, zinc, and aluminum to a clear plastisol ink to print the desired design onto your choice of fabric or solid material.

Foil/Reflective

A little different from the previous method, foil printing is a two-step process whereby a layer of gold or silver leaf is added over a layer of special adhesive in place of regular ink. These reflective leaf foils give highlights and enhances the print. Foil also works well with water-based inks.

Puff

Puff is an additive that literally ‘puffs’ up while being cured – creating a soft and raised feel. It produces strong and long-lasting ink film with a high uniform finish as well as good abrasion resistance.

Discharge

This is a water-based ink that chemically removes the dye from the pigment of the fabric, replacing it with the dye of the ink color.

So which method will you go with?

Now that you know a little bit more between screen printing vs heat press vs Direct-to-Garment printing – how you move forward largely depends on where you currently stand, and what your future goals and expectations are.

Are you a hobbyist? Heat pressing and screen printing are both excellent methods you can easily. Each have their own pros and cons as written above so take your time and try them both out. To help anyone get started, here’s a complete tutorial on how to screen print t-shirts at home.

Have a design in mind and want to start selling it on t-shirts? Approaching a heat press or DTG service provider will kickstart your project! Both methods work well especially for small batches so you don’t have to spend a lot of money to test your idea.

You want to create a garment decoration service. Going into business can be extremely exciting and rewarding. But make sure you know what you’re getting yourself into. You can set up a booth and sell heat press services or setup a screen printing shop.

But it doesn’t end here.

In addition to screen printing, heat pressing and DTG, there are other decorative methods that are being used to compliment specific styles.

I’m pretty sure you’ve seen a few of these around but can’t really tell how they work, until now.

9 types of garment decoration you’ve seen, but never knew what they were

Debossing

Popular in leather garments, debossing works by pushing a cut dye into the material surface in order to create an impression of the design.

It can also be done in conjunction with other kinds of decoration.

For example, a garment can be screen printed and later have the image debossed.

Overall, it is not as complicated as embossing and allows you to create unique effects.

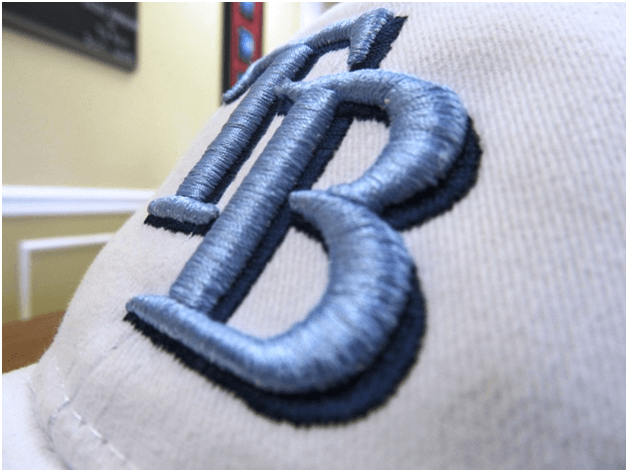

Embroidery

Embroidery designs can enhance the appearance of garments, particularly of kids’ apparel.

Embroidery is normally priced by the number of stitches in its design.

This is because the more stitches it has, the more time it takes to produce, and thus the higher the price tag.

Laser Appliqué/Etching

Laser cutting can create design-specific appliqués in just a short time. All you need is the digital design file that will communicate to the laser cutter like a printer. The laser will then apply a controlled burn to the fabric, searing its edges where the material should be cut.

With laser etching, fabric choice is an important consideration. Twill is the best since it will not discolor and burn. However, anything with cotton batting might catch fire from the heat. Otherwise, both synthetic and natural materials can be used.

Reverse Appliqué

The opposite of traditional applique, with reverse applique you place a design or patch beneath the material, instead of the top. The fabric above the applique is cut away and leaves a multi-dimensional appearance.

Photo Stitch Designs

This is an embroidery technique where you scan a photo, input it into a digitizing software, and printing it to an embroidery machine.

It can be used to create almost any design and allows for multiple colors as well.

The finished piece will look less like traditional embroidery, but more like a drawing or painting.

Tackle Twill

This is a popular style for sports jerseys. With tackle twill, the designs are cut off from the twill fabric and placed to the surface of another fabric material using adhesive like appliques. The zigzag stitch around the design edge will keep it in place. Tackle twill is a good alternative to traditional embroidery since it has a low stitch count.

Trapunto

Trapunto is a type of embroidery that is characterized by a 3D look. It dates back to 13th century Italy and used on coverlets that did not need to be too heavy.

It involves creating a pocket between the material and backing the embroidery design, stuffing it with filling to create a raised fabric effect. Original trapunto designs include greenery such as vines and were widely used on quilts, clothing, and blankets.

Scalloped edging

The scalloped shades at garment edges such as hemline opening and necklines are made by cutting the desired shape and finishing it with shaped facing or bias binding. The effect of a scalloped front opening is achieved by drawing the scallops and working blanket stitches with the contrasting colored thread along the draw lines.

The scalloped edging is typically used in skirts, frocks, sleeves, and tablecloths.

3D Foam Embroidery

A relatively simple process, 3D foam embroidery is created by introducing a piece of foam material to the sewing process.

The stitches penetrate and lock the foam into the design making specific elements significantly raised up above the rest. You can find 3D foam embroidery mainly on sports caps and hats.

Wrapping up

The world of garment decoration is a wild one.

And even though I’ve covered a lot today, there are still a lot more that I left out due to their unpopularity.

Nevertheless, with this available list, you can always mix and match and find creative ways of enhancing the appearance of what you’re trying to achieve.

Whether you are thinking of producing for yourself or creating a product to sell, your knowledge of what can and can’t be produced by each decorative method will go a long way in how you will deal with your customer’s needs as well as avoiding costly mistakes.

Let me know if the comments what you come up with!