You can have the best press, best dryer, best exposure unit, best everything in the world, but if you don’t have a sharp, clean squeegee blade, your print will look bad no matter what…

Now who would think that something as simple as the screen printing squeegee would have such a big impact on the overall printing process and print quality?

Yet it’s true. And we quite often take this small piece of rubber for granted.

Most screen printers produce tens of thousands of strokes without ever evaluating their printing squeegee because it just “seems to work,”. Until a major setback happens.

So today we’re answering 15 common squeegee questions many beginners (and intermediate) printers have never thought to ask.

Hopefully after this, you’ll look at the squeegee as something more than a tool that pushes ink through a screen mesh.

Top screen printing squeegee questions you need to know

1. What kind of squeegee shape or tip should I get?

Screen printing squeegee blades come in three different shapes – squared, rounded and angled.

Square tips or straight edged tips are common all-purpose ones. These blades have a flat bottom and are used for most screen printing jobs producing sharp and clear prints. These are perfect if you’re printing standard and regular ink applications.

Rounded blades are typically used for laying down heavier ink e.g. white under-base on dark colored garments, or specialty type inks e.g. puff or high density plastisol ink. This type of blades are great for spot colors as it generally pushes more ink through the mesh.

Finally, angled squeegees (beveled or “V” shaped) are used for prints with fine lines, detailed artwork or irregular styles of substrates.

Most printers own squared and rounded squeegees in different sizes as most t-shirt screen printing require only these two.

2. Which squeegee size is the best for me?

Squeegees come in different lengths and sizes. When it comes to picking out squeegees, here’s the math:

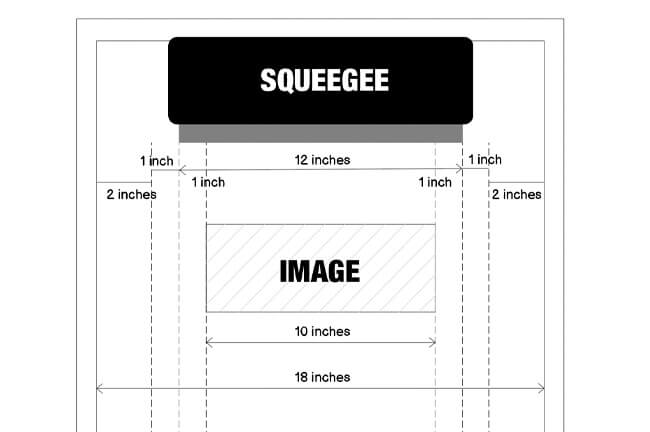

It is recommended to have at least an extra inch on each side from the edges of your image and the ends of the squeegee. Also, allow at least 2-3 inches on each side between the squeegee and the frame.

For example, if your image print is 10 inches wide, you need a 12 inch squeegee with a screen width of 18 inches or more.

Again, this is what’s recommended. The bottom line is, you should get a squeegee that’s larger than the print and have enough wiggle space from the edges of the frame. Keep in mind that the squeegee must not be too close to the frame as this can destroy the tension of the screen.

3. When should I replace squeegee blades?

Constant exposure to inks and solvents, on top of normal wear and tear will swell, weaken and warp these rubber blades. That said, you almost never need to replace squeegee blades until it is clearly damaged – broke, torn, chipped, etc; instead sharpening is recommended since it’s more cost-effective and better for the environment.

If you notice some streaking, heavier ink deposits, a reduced sharpness in print or irregular image print e.g. light or dark areas in the print, it could be time to clean and sharpen the squeegee blade.

But keep in mind not to sharpen the squeegee right after cleaning. As it’s still soft and probably contains solvent residue, let it rest for 12-24 hours. This will improve the sharpening process and also the squeegee’s performance.

4. How do I sharpen my squeegees?

There are several different ways to sharpen a squeegee from diamond wheels to blade cutters, grinding belts to polishing cloths. But unless you operate a shop and can benefit from owning one of these sharpening tools, it’s best to send it to a professional. The time it takes them is probably the same amount of time it takes you to set things up.

5. How often should I sharpen my squeegee?

In my opinion, when you see a drop in squeegee performance or notice any of the symptoms I’ve mentioned before, things like streaking, dull prints, etc.

But really, there are no “rules” for how often a squeegee should be sharpened. In general, it is unlikely that a squeegee can perform at all over 50,000 strokes. To maintain quality printing I suggest evaluating the rubber every 5,000 strokes.

6. What does squeegee “durometer” mean and which should I use?

Durometer is the measure of hardness or softness of a screen printing squeegee’s blade. It has a numerical value ranging from 55 to 90 with 55-65 considered soft, 66-75 for medium, and hard for anything over 75.

Soft blades are designed to deposit more ink onto the substrate. For example laying down a thick layer of white under-base on a black t-shirt or printing specialty ink such as puff. It should also be used on textured fabrics or rough surfaces as the soft durometer blade easily adapts to the screen mesh.

For general screen printing jobs, the most commonly used squeegees are in the Medium range, typically 70. Start with this durometer if you’re just learning how to screen print as it’s useful for a wide range of screen meshes and different ink types.

Harder blades above 75 durometer will deposit less ink and are commonly used for prints with fine details or for process screen printing. These types of squeegees are also used on higher mesh count screens with high tension.

7. Should I use wooden, plastic or aluminum handles?

Since this is a personal choice I would say test them all if you have the chance. You want something that’s robust and holds up well while printing, and also one that is ergonomic and feels comfortable in your hand.

Wooden handles are cheap, abundant and are my favorite type because I’m just used to them in general. However, they are difficult to clean once you get ink on them. Alternatively, plastic or aluminum handles are easier to clean but cost significantly more. Replacing or swapping out blades on them are also easier compared to squeegees with wooden handles so take that into consideration as well.

8. Are squeegee holders necessary?

Many will say it isn’t, but I think it’ll improve your work flow and work space immensely. It may sound insignificant, but having a proper mounting place for your squeegee will directly contribute to your efficiency as a printer. Never have a squeegee fall, make a mess, or drip ink all over the place anymore. It’s really a no brainer for something as useful as this.

9. I can’t keep my frame in place after each stroke!

Make sure to check your press or clamps if you notice your image moving off registration. If things look fine in that area, it could be due to having too much squeegee pressure.

Make sure to apply force, but not too much. Squeegee durometer can also have an impact on the pressure. Harder squeegees tend to have more drag on screen so you may benefit from a softer squeegee. Finally, check the squeegee size and ensure you’re not using one which is too wide for your screen frame. If so, this might be the cause of shifting.

10. How do I hold the squeegee properly?

There is no hard and fast rule for this. Personally, you should feel the most comfortable and natural while still being able to perform the task. If you’re holding a full size squeegee (10” or more) you should ideally be using both hands to maintain balance and pressure. When you’re using only one hand for smaller sized squeegees, make sure it firmly fits into your entire palm and fingers. This way, you will have optimum control of dealing with pressure and angles.

11. How do I move the squeegee?

The best way to squeegee is to maintain a nice, even pressure and a relatively quick, smooth stroke. Keep in mind that pressure and angles depend on the type of squeegee. Also, modifying both will directly affect the amount of ink pushed through the mesh and sharpness of print. On a general note, the more downward angle means more ink will be pushed through the mesh but the less sharp the print will be. Like anything, finding the right balance takes practice.

12. Should I push or pull the squeegee?

I previously wrote an entire article on this. Please check it out.

13. Why do my wrists hurt when I’m printing?

People who manually screen print are at risk of developing wrist pain, carpal tunnel syndrome, or tendonitis. Because squeegeeing is a repetitive motion, chances are the pain is a result of poor form over a long period of time. I’ve suffered through jobs in the past where the pain was so sharp, I had to delay orders so I could recover.

One thing to learn is how to relax your grip. Avoid gripping the squeegee too tightly and be conscious about it while printing. Another way to prevent injury is to make sure your wrists aren’t bent excessively. Check the level of your press or adjust the height of the table so your wrists are naturally straight. Also, it helps to perform some wrist strengthening and stretching exercises before, during and after a printing session.

14. How do you clean a squeegee blade?

You should always clean squeegee blades immediately after you’re done and while the ink is still easy to remove. Leaving ink or solvent on the blades will over time ruin them and scraping off dried ink can damage the blade. Always use the proper cleaning chemicals and proper brushes to clean the blades so the squeegee rubber does not swell and warp.

15. How should I store my squeegees?

Always store your squeegee blades facing upwards and never on the blade itself. This is where a squeegee holder comes in or you could prop it up on a shelf. Just make sure there is no pressure on the squeegee blade during storage. Also keep them clean and dry in a cool environment. Proper storage can help squeegees retain their shape and extend their lifespan.

Wrapping up

Hopeful with the squeegee questions above, you now see the importance of this rubber in your day-to-day as a printer.

With a little bit of maintenance and upkeep, your squeegee will give you consistent performance and print quality.

It’s also recommended that you have a few squeegees lying around. This gives you the chance to rotate them frequently in between printing and cleaning.

Again, let them rest between 24 to 48 hours after cleaning as this will allow it to dry out and return to its original shape.

There are just too many probabilities and small oversights when it comes to screen printing.

Let’s control what we can do, especially when it comes to the squeegee-blade, as spotting trouble so late in the workflow means downtime and loss of revenue.

CommentNice Article!! Thank You so much for this article it clarifies all the questions regarding Squeegee Blade for Screen Printing. I’m sure this article will be very helpful for me and many people who are looking for this product